Fmea Course

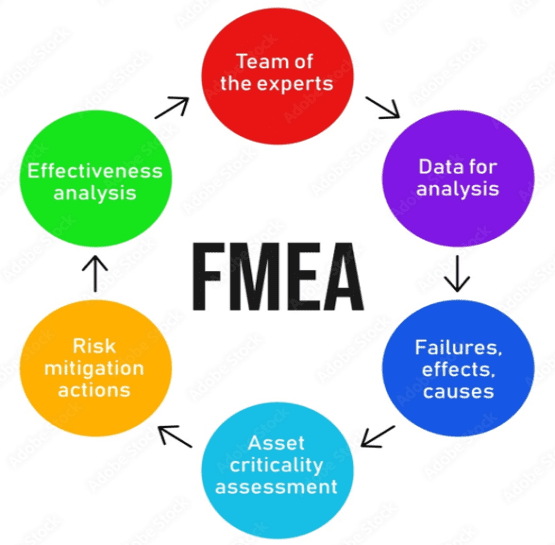

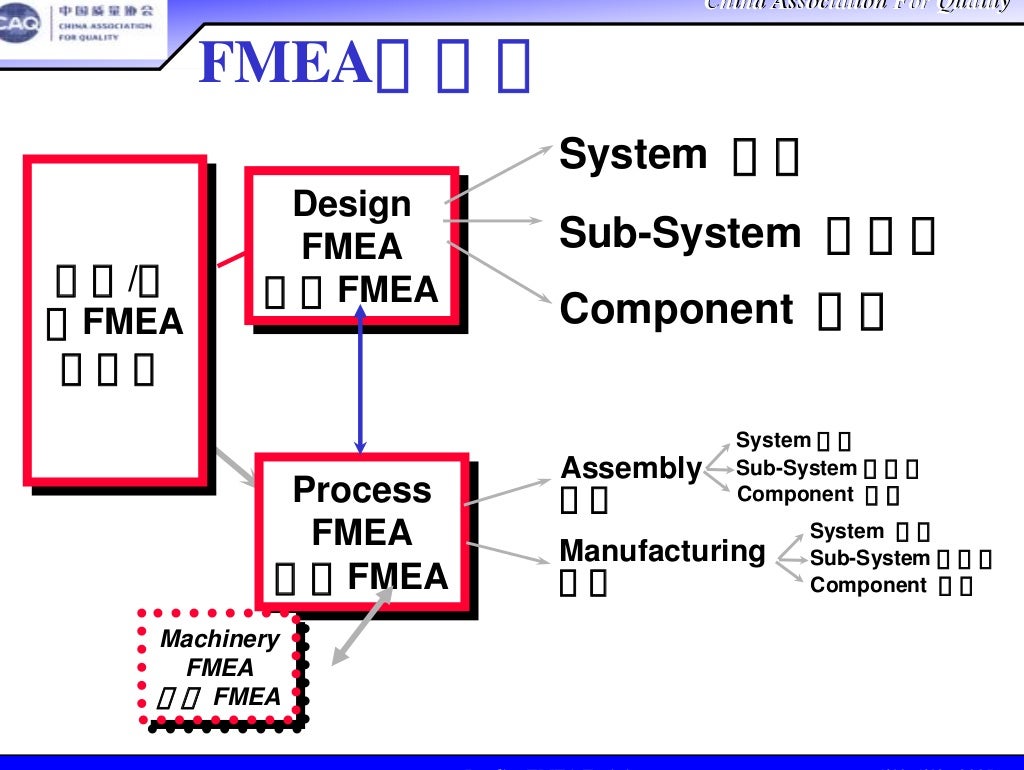

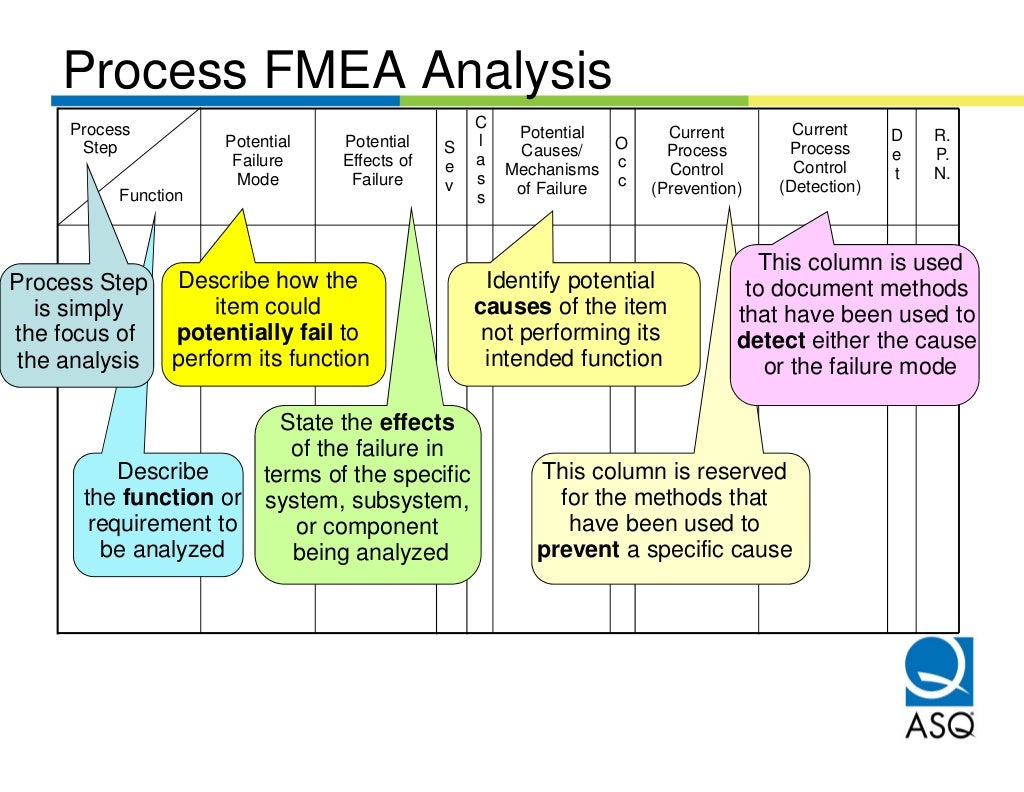

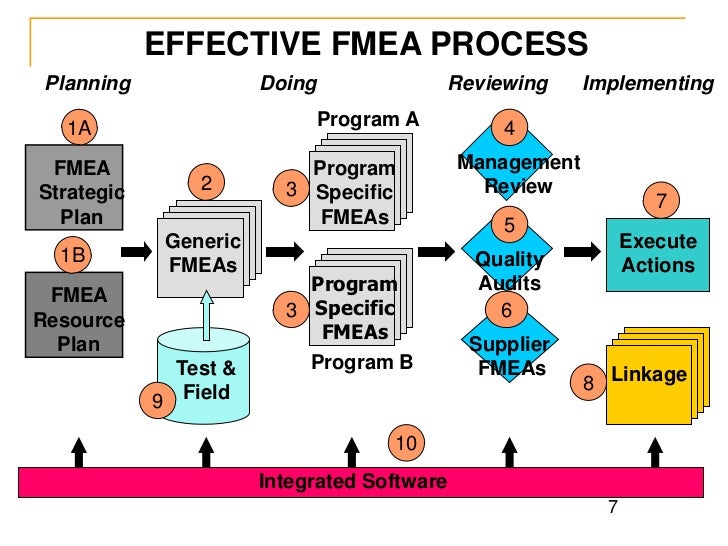

Fmea Course - ‘ fmea ’ stands for failure mode and effects analyses and includes a special type of analysis called failure mode, effects and criticality analyses or fmecas. Just solid training when you need it. Up to 10% cash back failure mode and effects analysis (fmea) is a methodical and systematic technique that helps in identifying predictable failure modes and either eliminates them or at least minimizes them. This course will guide you in the effective use of failure mode and effects analysis (fmea). Online fmea training for your team following aiag's fmea 4th edition. The individual is able to apply and communicate the methodology and, as a result, successfully support the identification and management or risks. Quality alertsunlimited userscustom checks effortless Practice of efficient fmea development using a. Acquisition of knowledge of fmea and its proper use; Fmeaexam | competency qualification by aiag in fmea 4th edition verifies an individual's competency in failure mode and effects analysis techniques as defined in aiag's fmea 4th edition reference manual. If you have questions related to the details of this course, such as cost, prerequisites, how to register, etc., please contact. Acquisition of knowledge of fmea and its proper use; Commitment to the prevention of failure using fmea; Identify potential software failures and their effects. Failure mode and effects analysis (fmea) training course overview: Up to 10% cash back failure mode and effects analysis (fmea) is a methodical and systematic technique that helps in identifying predictable failure modes and either eliminates them or at least minimizes them. 24 hour supportinspection scheduling100% customizablereal time insights We have acquired our fmea knowledge by being in the forefront of quality and reliability, specifically fmea, for over 30 years. Proven track recordglobal expertise25+ years experience Make fmea at your project’s core today with our lean six sigma and dmaic courses. Fmeaexam | competency qualification by aiag in fmea 4th edition verifies an individual's competency in failure mode and effects analysis techniques as defined in aiag's fmea 4th edition reference manual. Fmea training describes failure mode and effects analysis so chicago students can lessen risk while designing any new system, product, or process. Up to 10% cash back failure mode and. Make fmea at your project’s core today with our lean six sigma and dmaic courses. Up to 10% cash back failure mode and effects analysis (fmea) is a methodical and systematic technique that helps in identifying predictable failure modes and either eliminates them or at least minimizes them. If you have questions related to the details of this course, such. The individual is able to apply and communicate the methodology and, as a result, successfully support the identification and management or risks. Acquisition of knowledge of fmea and its proper use; Commitment to the prevention of failure using fmea; Online fmea training for your team following aiag's fmea 4th edition. Evaluate the severity, occurrence, and detection of software failures. Online fmea training for your team following aiag's fmea 4th edition. Join 69m+ learnersstay updated with aistart learning todayexpert instuctors Up to 10% cash back this is a really comprehensive course on fmea that will teach you how to conduct professional fmea in just 2 hours! ‘ fmea ’ stands for failure mode and effects analyses and includes a special. Practice of efficient fmea development using a. Failure modes and effects analysis (fmea) is a tool that can identify product and process failures before they occur, identify appropriate risk mitigation measures to prevent or otherwise control the failure, and improve product and process design. Failure mode and effects analysis (fmea) training course overview: Fmea training describes failure mode and effects. 24 hour supportinspection scheduling100% customizablereal time insights Quality alertsunlimited userscustom checks effortless Up to 10% cash back in this course, we will cover: The individual is able to apply and communicate the methodology and, as a result, successfully support the identification and management or risks. Practice of efficient fmea development using a. Identify potential software failures and their effects. The individual is able to apply and communicate the methodology and, as a result, successfully support the identification and management or risks. No expensive travel or days in the classroom; Online fmea training for your team following aiag's fmea 4th edition. 24 hour supportinspection scheduling100% customizablereal time insights Failure modes and effects analysis (fmea) is a tool that can identify product and process failures before they occur, identify appropriate risk mitigation measures to prevent or otherwise control the failure, and improve product and process design. Acquisition of knowledge of fmea and its proper use; Identify potential software failures and their effects. Online fmea training for your team following. Identify potential software failures and their effects. Here is why this course is unique compared to everything else on the marketplace: Quality alertsunlimited userscustom checks effortless We have acquired our fmea knowledge by being in the forefront of quality and reliability, specifically fmea, for over 30 years. Apply the principles of failure modes and effects analysis (fmea) to software systems. Fmea training describes failure mode and effects analysis so chicago students can lessen risk while designing any new system, product, or process. Valuable techniques are introduced as you move through the fmea. Make fmea at your project’s core today with our lean six sigma and dmaic courses. We have acquired our fmea knowledge by being in the forefront of quality. Quality alertsunlimited userscustom checks effortless A fmea strategy is comprised of three elements: Valuable techniques are introduced as you move through the fmea. Up to 10% cash back failure mode and effects analysis (fmea) is a methodical and systematic technique that helps in identifying predictable failure modes and either eliminates them or at least minimizes them. Up to 10% cash back in this course, we will cover: Fmea training is part of a successful fmea strategy. Acquisition of knowledge of fmea and its proper use; Identify potential software failures and their effects. Learn the steps and actions needed to conduct an fmea for processes within your organization. Practice of efficient fmea development using a. Just solid training when you need it. No expensive travel or days in the classroom; Commitment to the prevention of failure using fmea; ‘ fmea ’ stands for failure mode and effects analyses and includes a special type of analysis called failure mode, effects and criticality analyses or fmecas. Failure modes and effects analysis (fmea) is a tool that can identify product and process failures before they occur, identify appropriate risk mitigation measures to prevent or otherwise control the failure, and improve product and process design. 24 hour supportinspection scheduling100% customizablereal time insightsFMEA Training Business Manufacturing And Engineering

FMEA Training Failure Mode and Effects Analysis

FMEA training training for companies PROQUAL Management Institute

Fmea training material

FMEA Training Course Onsite or Online Dfmea or Pfmea QualityOne

Fmea presentation

FMEA Training Failure Mode and Effects Analysis Training QualityOne

How to implement an effective fmea process

Theory Fmea Presentation Format Stock Vector (Royalty Free) 1790880986

FMEA Training Failure Mode and Effects Analysis Training QualityOne

Failure Mode And Effects Analysis (Fmea) Training Course Overview:

We Have Acquired Our Fmea Knowledge By Being In The Forefront Of Quality And Reliability, Specifically Fmea, For Over 30 Years.

Apply The Principles Of Failure Modes And Effects Analysis (Fmea) To Software Systems.

Here Is Why This Course Is Unique Compared To Everything Else On The Marketplace:

Related Post: